With the best acoustic foam alternatives, you can enjoy highly effective, cheap soundproofing materials for your studio or any space.

Acoustic foam panels are excellent to use for fine-tuning the sound in a room. They help to get rid of unwanted echoes and other problems caused by reflective surfaces.

However, acoustic foam panels are not very good at soundproofing a room because soundproofing is achieved by reducing the vibrations caused by a sound coming from outside a room.

The other concern is that foam panels are somewhat expensive compared to other sound treatment solutions.

The good news is you don’t need to spend that much money to soundproof your room and reduce noise leakage.

In this article, I’ll show you how to use better alternatives to acoustic foam that offer cheap soundproofing materials to fit your budget.

I have been producing podcasts for many years. Making podcasts is not something I did to earn money, and I had to do everything on a very low budget. I tried all kinds of things to soundproof my home studio.

Read more to learn about getting the perfect sound for your home recording studio by using all kinds of things as an alternative to acoustic foam or in addition to using acoustic foam.

Disclosure: Some of the links in this article are affiliate links, meaning at no additional cost for you, we might get a commission if you click the link and purchase.

What is acoustic foam and how does it work?

People think acoustic foam is for soundproofing. This is a common misunderstanding. It can help with improving a room’s sound, but soundproofing is not its main purpose.

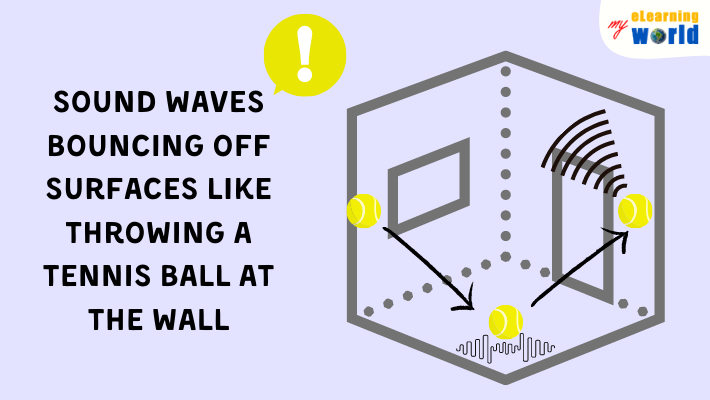

The main reason to use acoustic foam is to stop sound waves from bouncing off the reflective surfaces in your recording studio and fine-tune the frequencies.

Think of sound waves bouncing off surfaces like throwing a tennis ball at the wall. The ball would bounce and perhaps hit another surface and bounce again.

Sound waves do this also, just invisibly. As a sound wave reflects from a surface, it may hit another surface and bounce again. Now you have all the interference patterns of the sound waves mixing, making a jumbled mess.

If a sound wave hits an acoustic panel, the angle of the foam panel’s bumpy design or the absorption of the soft material catches the sound wave and does not reflect it. Think of these panels as acting like a catcher’s mitt that catches the tennis ball thrown at it.

To choose acoustic foam panels, you want to evaluate these things:

- Flat Panels: Flat panels absorb sound based on their thickness.

- Sculpted Panels: Sculpted panels absorb more sound based on the design. They may have ridges, pyramids, or look like an egg crate.

- Thickness: Panels come in one-, two-, and four-inch thick styles. Thicker panels absorb more sound.

- Noise Reduction Coefficient (NRC): This is a scientific measurement of how well the material absorbs sound. The NRC measurement has a range from zero to one. Zero is no absorption. One is full absorption. A good NRC rating is 0.75.

- Size: Typically, sound panels come in 24-inch squares or multiples of that size. Bigger sizes are simply more convenient to use when covering large surfaces.

- Color: Acoustic sound panels in different colors can be used to make a recording studio more attractive.

If you want to find the best acoustic panels you can get my recommendations here.

Cheap Acoustic Foam Alternatives

Here are the things that I have tried as alternatives to acoustic foam tiles for soundproofing materials.

Some materials, which are heavier and denser, are better for soundproofing purposes.

Other materials are better for their sound absorption characteristics to help fine-tune the room sound.

One note of caution is appropriate to consider before we begin to talk about materials. Be aware that you may create a fire hazard.

For example, if you stuff the walls with paper, you can block some sound from coming in from outside; however, if the paper is not treated with fire retardant, you severely increase the risk of a fire.

To avoid creating a fire hazard, use fire-rated materials for safety and treat the materials with fire retardants to reduce their combustibility.

Here are some acoustic foam alternatives to consider that are great cheap soundproofing materials:

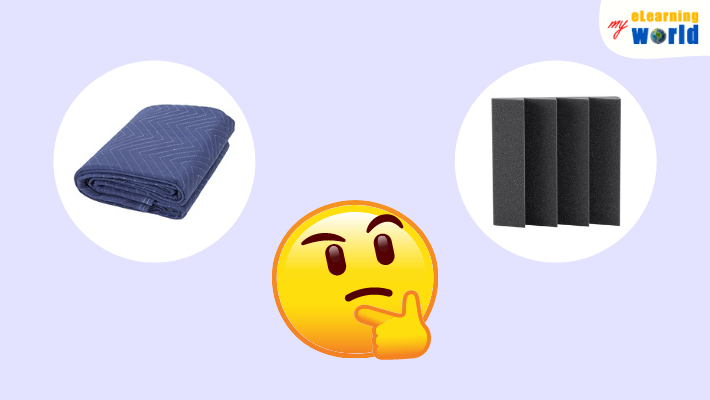

1. Heavy-Duty Moving Blankets

Heavy-duty moving blankets are a good choice because they are so cheap. If new, they only cost about $6 each for the 72- by 80-inch size. You can sometimes find used ones for sale at bargain prices.

You can use moving blankets to stuff the walls, cover wall surfaces, or hang them like curtains. You can hang them from hooks on the walls, and then they can be taken down and moved around.

All in all, heavy blankets are fantastic cheap soundproofing materials.

2. Scrap Materials

Any type of dense material that can be fire-treated is suitable for using as soundproofing material to fill the walls. These can be various fibers, used cement, wood scraps, sawdust, packing materials, and some recycled materials.

Any dense material that can be used in thick walls provides a barrier that reduces the ability of sound to pass through.

In a newly built professional recording studio, the rooms are floated on a suspension system that creates minimal contact with the support structures. Thick concrete walls are used to separate recording studios from other rooms.

In a home recording studio with enough physical space to isolate the room, a false wall can be built inside or outside the existing wall. The space between the two walls can be filled with any available scrap materials.

3. Putting Carpet on or in the Walls

In a permanent home studio installation, it may be possible to put carpet inside the wall. Be sure to use a fire-retardant to treat the carpeting, and then you can fill the walls with it.

To improve soundproofing, the idea is to reduce the vibrations that are transmitted through materials and reduce the air that comes in from outside. Sound travels through the air by vibrating the air molecules. Sound travels through other materials by vibrating them also.

The thicker and denser the material is the less vibration that can pass through it. The more layers there are, with a gap of air space between them, the more control you have over blocking sound and vibrations.

Install carpeting on the wall on one side, place carpeting inside the wall, and then install carpet on the other side of the wall to achieve an excellent result.

You can use carpeting on the floors and ceiling in a similar way to reduce sound vibrations coming from above or below. The carpeting does not have to be new.

Try to talk with some local carpet installation companies. They may give you used carpeting for free because they have to pay to throw it away.

4. Egg-Crate Mattress

These mattresses and mattress covers (like this one) are foam that looks like an egg crate. If you buy this material new, it is about the same price as acoustic foam.

However, you may also find a mattress company that will give you the material inside the old mattresses for free or cheap.

Used mattresses cannot be sold to another person to use for sleeping due to health safety issues. A company that sells new mattresses has to remove the old ones. Then, they have to dispose of the old mattresses.

Usually, they tear them down into components and recycle the metal parts. But the foam is often thrown away. This may be a source of materials that you can get free or cheap to use for soundproofing and blocking sound leakage from your space.

5. Egg Carton

If you eat eggs, save the cartons, and then you can put them up on your home studio walls to help fine-tune the room. These cartons are made from surprisingly effective sound absorbing materials.

For example, you can glue them onto a concrete wall to reduce the sound reflections coming from that wall.

The egg cartons can be painted or covered with a spray texture to change the sound dynamics of the material. You can read more about this method in this article about using egg cartons as a soundproofing material here.

6. Cup Holders

The types of cup holders that work for this purpose are made out of the same material as the egg crates. You may be getting these as a carrying tray when you buy drinks from a fast-food restaurant.

The reason these work to absorb sound comes from their shape. They trap incoming sound in the same way as acoustic panels that have an egg-crate style or pyramid style.

The sound waves coming toward them hit the angular surface of the cup holder and, instead of bouncing straight back, go on a reflected angle to hit the surface of the cup holder again.

This re-direction of the momentum of the sound vibration and sound absorption allows the noise to be reduced when it comes into contact with the materials.

7. Clear Plastic

Clear plastic, which is useful for sound insulation, includes solid PC sheets, acrylic sheets, plastic-coated glass, layered glass with plastic between glass layers, and transparent composite materials.

None of these materials are cheap unless you find them as recycled building materials. You may want to have a clear window between rooms in your recording studio.

In most recording studios, a small window is installed in the wall of the vocal isolation booth. This allows an audio engineer to see the performer when working at the mixing board or audio interface/computer in the other room.

Such a window for a vocal isolation booth can be tall and narrow to use as little clear plastic as possible.

Install this window in such a way as to block any air leakage from passing around the window edges from inside the vocal isolation booth. If air can get out of the room, so can the sound.

8. Green Glue

Green Glue is a noise-proofing system used with new construction or remodeling to reduce noise transmission between rooms significantly. It works by reducing the transfer of structural vibrations caused by sound waves as they pass through the walls, ceilings, and floors.

There are four products: noise-proofing clips, noise-proofing compound, noise-proofing sealant, and joist tape.

The noise-proofing clips disconnect direct contact between one side of the wall and the other side, which reduces the amount of sound transferred by the framing. Each side of the wall vibrates independently.

The noise-proofing compound is used between two layers of materials: drywall, cement board, or plywood. It works best with thicker materials that are rigid such as 5/8-inch sheetrock mounted on 3/4-inch plywood.

The noise-proofing sealant is used to fill a 3/8-inch gap around the perimeter of a wall or ceiling. This method creates an acoustical seal and is a great way to soundproof a room.

The joist tape is used on the top of the floor joists to reduce any squeaks when the subflooring rubs on the joists.

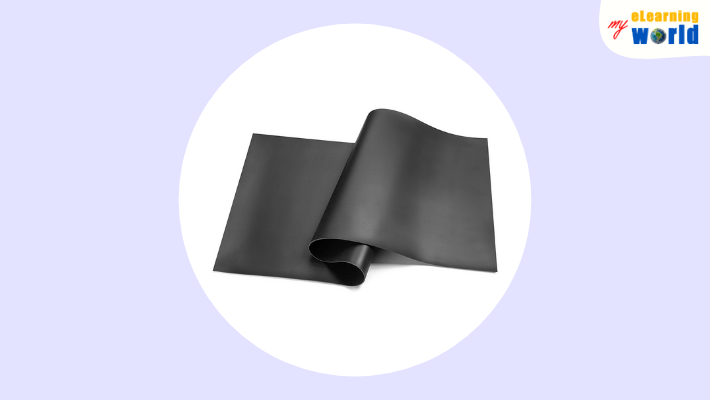

9. Mass Loaded Vinyl

Mass Loaded Vinyl (MLV) is a vinyl material with embedded metal particles used to increase the mass. It comes in rolls. You can use MLV to add mass to walls and ceilings for soundproofing. It’s a very effective way to block sound.

MLV reduces the transmission of sound through walls, ceilings, and floors. It is flexible and easy to cut into pieces.

MLV can be hung on existing walls. It performs the best when it is sandwiched between two drywall layers. It can also be installed under the carpet between the floor and the carpet pad.

10. Sound-Deadening Spray or Paint

The sound-deadening spray is used to reduce the transmission of sound through metal. One application of sound-deadening spray is to stop a rattling noise coming from the air ducting system.

Sound-deadening paint, which may come as a spray or in buckets, works on a different principle. It is meant to be applied to walls to increase the wall’s mass. When a wall’s mass increases, this reduces the sound vibration that can pass through the wall. This can go a long way to soundproof a room.

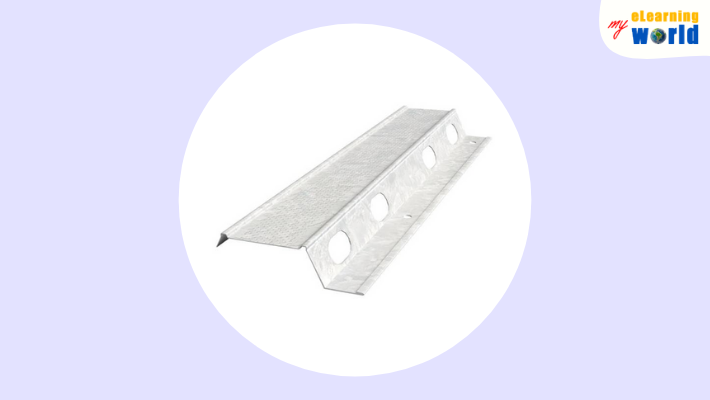

11. Resilient Channel

Resilient channel is a thin metal channel installed between the wall or ceiling joist and the drywall to create an air void between the two surfaces.

Resilient Channel is especially useful if you want to have a home recording studio below another floor. You can use this to reduce the sound of walking from the floor above your home studio by up to 90%.

You have to be careful when installing Resilient Channel because if you use the wrong length of screws or install it incorrectly, you may defeat its effectiveness.

12. Anti-Vibration Pads

There are many kinds of anti-vibration pads and mounts. They can be used to isolate vibrations and not transfer them to another part of the structure.

For example, you may have a home recording studio in the basement, and in another adjacent room, there is the laundry area with a washing machine and a dryer.

You can use anti-vibration pads under the legs of the appliances to keep these vibrations from transferring to the floor or the walls. This will block sound and stop the vibration from passing into the other room where you have your studio.

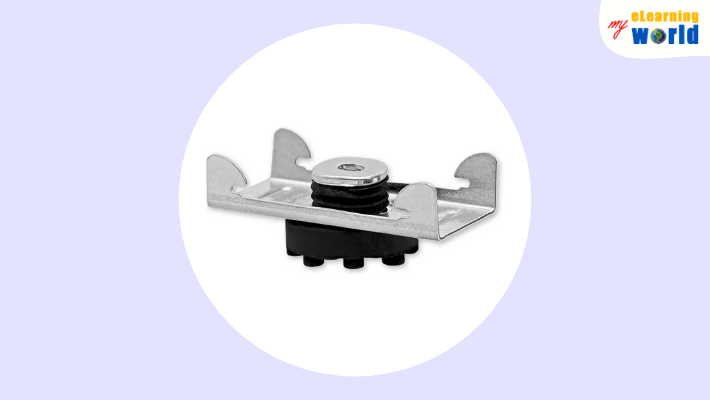

13. Sound Clips

Sound clips are used to decouple the vibration of walls and ceilings from other structural components. When each side of a wall can vibrate independently.

Sound clips perform better than a Resilient Channel when used with insulation. The enhanced performance comes from having fewer contact points to transfer sound.

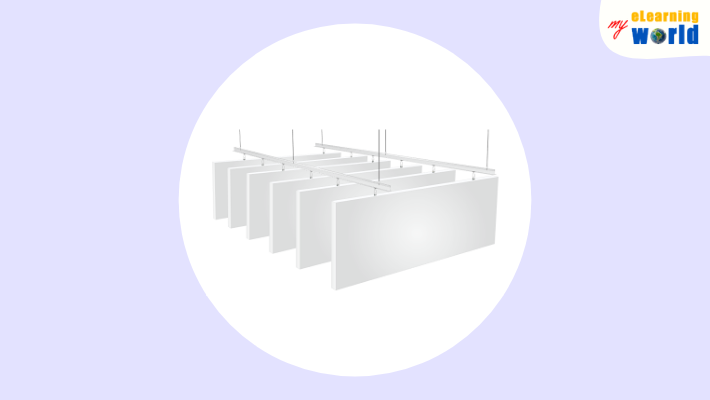

14. Ceiling Sound Baffles

Ceiling sound baffles can be made of foam, fiberglass, or cotton. A baffle can be layered with different materials and covered with acoustic fabric. Large ceiling baffles may contain an aluminum frame for increased structural strength when hanging them.

They are used to improve the sound of speech in the room and give it more clarity by reducing any unwanted echoes. If the purpose of the baffle is to diffuse the sound, it may have an abstract shape.

15. Soundproof Curtains

Soundproof curtains can be made of any thick material. You can use heavy fabric, moving pads, carpeting, and carpet padding.

Installing a soundproof curtain blocks sound transfer from one part of a room to another. An example is using a soundproof curtain in a theater so that the audience cannot hear what is happening backstage while the curtain is closed.

On a smaller scale, the convenience of using a portable soundproof curtain is that it can be mounted on hooks installed in a wall or on movable wall panels. It can be put up, taken down, and moved around for sound dampening as needed.

For example, you can isolate a loud instrument, such as a drum kit, by surrounding it with a soundproof curtain. This method helps reduce the amount of drum sounds picked up by other mics in the room, when recording a live band.

16. Weather Stripping

Weather Stripping is used around doors and viewing windows so that the air does not come through. This reduces the sound that would otherwise leak through the cracks around doors and windows.

Do you use acoustic foam or cheaper alternatives?

I have used both. When choosing soundproofing materials, focus on whether you need to stop the air, the vibrations, or both.

There are four categories of soundproofing materials, which are:

- Sound Absorption: Lightweight porous materials that capture sound within the room.

- Transmission Reduction: Systems that decouple one part of the building’s structure from another part.

- Vibration Reduction: Materials that reduce vibration transmission.

- Dampening: Materials that dampen noise and block unwanted sounds coming from the exterior of a room or a certain sound source.

Useful Resources

- Different types of acoustic foam

- What are noise curves?

- How to make high-performance sound absorption panels for $5

- How to build your own DIY acoustic panels

- The best cheap bass traps

- Egg carton soundproofing: Everything you should know

A Final Word on Cheap Soundproofing Solutions

The acoustics of a room can be fine-tuned using a variety of methods and materials. Use these techniques and materials to isolate the room from the outside noise and annoying sounds. Use different treatments of the surfaces within the room to reduce unwanted echoes and absorb noise more effectively.

To stop vibrations, think about creating a gap between the thing making the vibration and the rest of the room.

To stop echoes, think about using something soft to absorb the sound, hitting any reflective surfaces in the room.

Have fun with this, and don’t be afraid to try different materials to reduce background noise, echoes, vibrations, and other interior and exterior noise pollution.

Have any questions about acoustic foam alternatives and cheap soundproofing materials? Let us know by leaving a comment below.